Behind the scenes of Guidotti hinges

Let’s stop in the workshop where Guidotti products are born.

This is where you will meet Nicole. His nimble fingers have delicately and precisely assembled each hinge for 16 years.

Don't try to tell her about it, she knows her products inside out ...

It is by following it that we will make you discover a know-how of excellence.

|

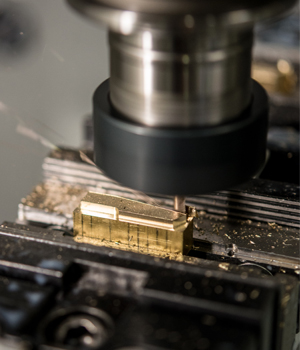

MACHININGThe machining of our hinges is carried out either in Revel (31) in our workshop, or by our subsidiary Serelec (83). |

||

|

FINISHESThe finishes includes the stages of polishing and chrome plating. These are two essential steps that guarantee both perfect aesthetics and resistance over time. |

||

|

ASSEMBLY100% of the hinges are assembled at Revel by Nicole's expert hands. We can thus offer you multiple configurations. Each hinge is manually tested, always to guarantee its function and quality. |

||

|

|

CONDITIONINGThroughout the creation and assembly stages, we take very particular care of its aesthetic aspect. |